Designing and Constructing the Kiln

The initial step was to design a kiln suitable for my work. Having some experience in kiln construction, I envisioned building an anagama-style kiln—a traditional Japanese wood-fired kiln where the firebox is connected directly to the chamber, allowing flames to pass through the ceramics before exiting through the chimney.

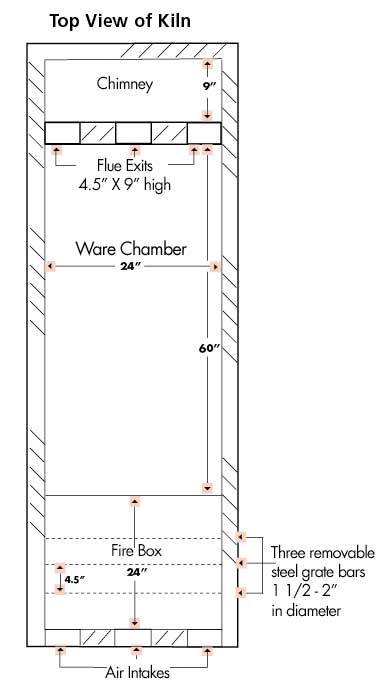

During my research, I discovered the Manabigama kiln, designed by John Thies. The Manabigama is a hybrid between an anagama and a groundhog-style kiln, featuring a crossdraft airflow system. Unlike traditional anagama kilns, which are often large and require multiple days to fire, the Manabigama is designed for more efficient small-scale firings. It reaches Cone 10-12 (1300°C-1350°C) in just 8-12 hours while consuming less than half a cord of wood. This makes it a highly effective kiln for both personal work and instructional settings. The kiln provides around 24 cubic feet of ware space, offering ample room for ceramic pieces (https://ceramicartsnetwork.org).

The Tradition and Science Behind Wood-Fired Kilns

Wood-fired kilns have been used for centuries in various cultures, including Japan, China, and Korea. These kilns differ significantly from modern electric or gas kilns because the firing process is highly interactive, requiring constant monitoring and adjustments. The process can take anywhere from 8 hours to several days, depending on the kiln type and size.

One of the most fascinating aspects of wood-fired kilns is the natural ash glaze formation. As wood burns, ashes are carried by the flame, melting onto the ceramics and creating unique textures and finishes that cannot be replicated with traditional glaze application. The longer and hotter the firing, the more pronounced the effects of ash deposition and flame movement on the ceramic surface .

Different types of wood-fired kilns include:

- Anagama Kiln – A single-chamber tunnel kiln, requiring continuous stoking over multiple days. Popular in Japan, it creates heavy ash deposits and varied surfaces on ceramics.

- Noborigama (Climbing Kiln) – A multi-chambered kiln built on a slope, where heat from the first chamber is reused in subsequent chambers. It allows for different firing atmospheres within the same firing process.

- Train Kiln – A modern adaptation of traditional wood kilns, featuring a more predictable airflow and greater efficiency in firing.

- Manabigama Kiln – A compact and efficient kiln designed for small-batch firings, reducing fuel consumption and making wood firing more accessible.

Construction and First Firing

Inspired by the Manabigama design, I selected a site and began sourcing materials. We obtained refractory bricks from an old brick factory and salvaged additional materials from an abandoned steel mill, where we dismantled parts of the furnaces.

However, poor drainage around the site created large puddles during heavy rains, delaying construction. Once we resolved this issue, we proceeded to lay the foundation for the kiln and began assembling its structure.

to be continued…

Leave a comment